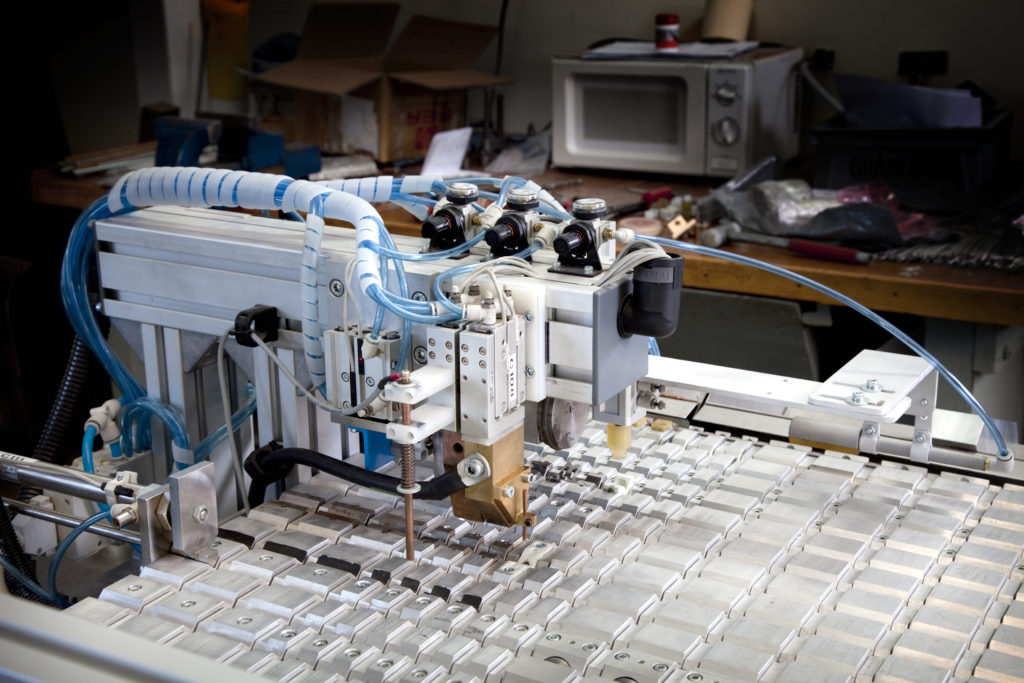

Home Automatic assembly unit, type KBMA

The unit assembles and welds two terminal pins to a coil as well as locating the bottom sealing plug onto the pin. Faulty or non assembled parts are automatically sorted out.

As an option, the KBMA can be equipped with resistance measuring (stretching the coil, measuring resistance and on the same time making a simple check that the coil is welded) of the ready unit after welding.

The normal cycle time is appr 3,5-4,0 s. Normal production during an eight-hour shift would be around 5000 – 6000 pcs.

This machine is only suitable for large batches, e g above 5 000 or 10 000 coils. Otherwise, the set-up time will become too important. However, if only the coil length varies, there is no need for a new set-up.

One week commissioning is a recommended option.

Switchboard: +46 16 16 72 00

E-mail: info@granlund.se

© Granlund Tools AB | Developed by Hamrén